Single vs. Double Acting Hydraulic Cylinders

In the heart of hydraulics lies the mighty cylinder, a piston-driven powerhouse that converts fluid pressure into linear motion. But within this realm of force, two distinct choices emerge: single-acting and double-acting cylinders. Choosing the right one for your application depends on understanding their fundamental differences.

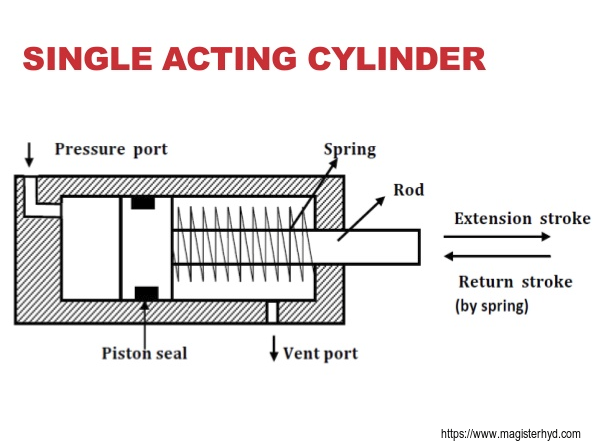

Single Acting Cylinders: One-Way Warriors

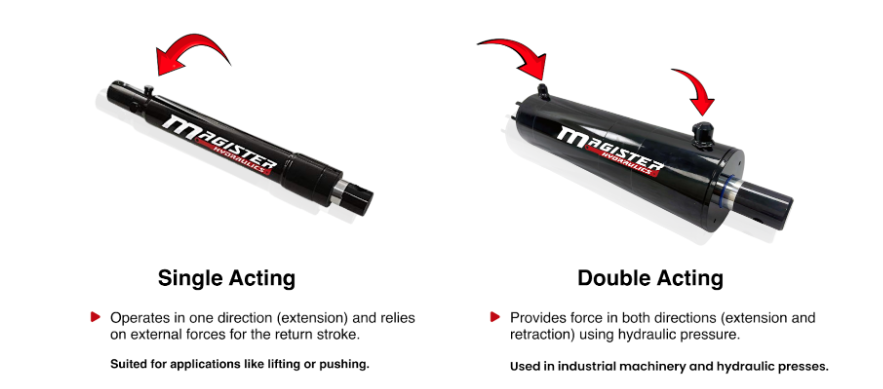

A single-acting cylinders are simple, affordable, and perfect for jobs where you only need force in one direction, like lifting boxes or clamping things down.

One Port: A single port controls both extension and retraction. Fluid enters, pushing the piston out, but needs to be released, allowing the external force to retract the piston.

- Lower Cost: Simpler design makes them more affordable.

- Limited Applications: Ideal for tasks requiring unidirectional force, like lifting, pressing, or clamping.

Double Acting Cylinders: Champions of Two-Way Force

The double-acting cylinder has two “fluid pipes,” allowing it to both extend and retract using hydraulic pressure. Picture a puppeteer pulling strings to control its movements, only with hydraulic fluid instead of yarn.

These dynamic cylinders are perfect for tasks where you need muscle in both directions, like opening and closing valves, moving robot arms, or operating machine tools. They’re more complex and costlier than their single-acting cousins, but their two-way power and precision make them worth the investment for many jobs.

Two Ports: Separate ports control extension and retraction. Fluid enters one port to extend, then exits through the other to retract, providing complete control over the piston’s movement.

- Greater Versatility: Suitable for tasks requiring bi-directional force, like pushing and pulling, opening and closing, or adjusting positions.

- Higher Cost: More complex design makes them pricier.

Making the Choice: Matching Your Needs with the Right Cylinder

So, which side should you align with? Here’s a quick guide:

- Single Acting: If your application requires force in one direction and can rely on gravity or an external spring for retraction, a single-acting cylinder offers cost-effective muscle. Think car lifts, log splitters, or simple clamping mechanisms.

- Double Acting: If your application demands bi-directional movement, precise control, or higher speed, a double-acting cylinder is your champion. Picture robotic arms, machine tools, or hydraulic presses.

Factors to be considered before selection of Cylinder:

Remember, choosing the right cylinder goes beyond just single vs. double action. Consider factors like:

- Force and Speed Requirements: How much force is needed, and how fast does the piston need to move?

- Stroke Length: How far does the piston need to extend and retract?

- Duty Cycle: How often and for how long will the cylinder be used?

- Environmental Factors: Will the cylinder be exposed to extreme temperatures, dirt, or debris?

Consulting with a Hydraulics Expert:

For complex applications or when unsure, don’t hesitate to seek guidance from a hydraulics expert. Their knowledge can help you navigate the diverse world of cylinders and ensure you choose the one that delivers optimal performance and longevity for your specific needs.

Remember, whether you seek the one-way might of a single-acting warrior or the dual-wielding mastery of a double-acting champion, understanding the differences between these hydraulic cylinders will empower you to select the perfect force for your application. So, go forth and conquer the world of hydraulics, one powerful piston stroke at a time!