Hydraulic Cylinder Dieseling

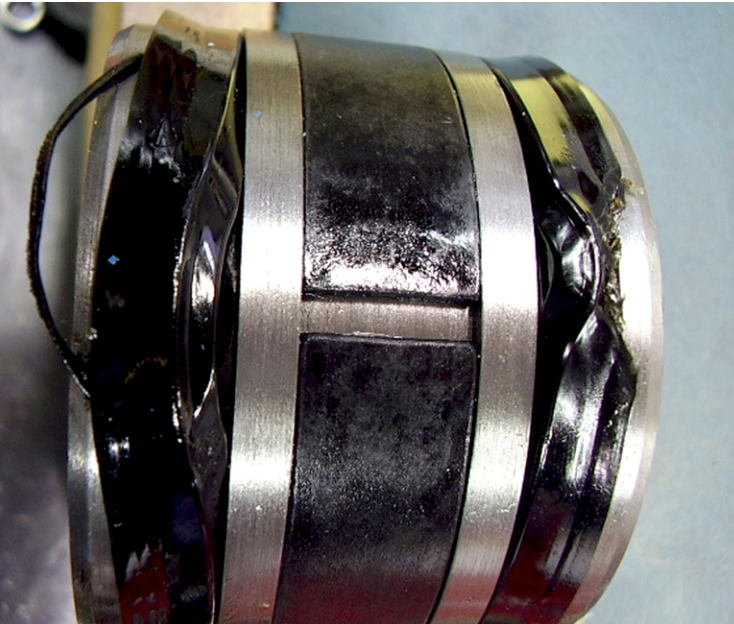

Hydraulic dieseling, often referred to as the dieseling effect, happens when air gets mixed with hydraulic cylinder oil, resulting in the formation of bubbles within the hydraulic fluid. Applying pressure to the system triggers a combustion event that breaks rod or piston seals and ignites quickly. This condition leads to the failure of the hydraulic cylinder. The explosive nature of this occurrence is similar to the ignition process observed in diesel engines, hence the term “dieseling.”

To reduce the risk of dieseling, it’s important to address potential sources of air entering the hydraulic system. Regular examination and maintenance of the hydraulic fluid, along with adequate cooling and ventilation, can help prevent the formation of air bubbles. Additionally, ensuring the correct selection of hydraulic fluid with suitable properties and maintaining the ideal operating temperature are essential practices in safeguarding against the dieseling effect.

Causes of Hydraulic Cylinder Dieseling

- Negative Pressure in the Hydraulic Cylinder: Occurs when the volume fluid demand exceeds the pump’s delivery capacity. It occurs in the development of negative pressure, drawing air past rod seals into the cylinder.

- Faulty float: valves are designed to minimize air intake but can be compromised if load control valves are faulty or improperly adjusted.

- Inadequately Purified Hydraulic Fluid Chambers: Inadequate purging of air from cylinder chambers during commissioning raises the risk of dieseling. Proper purging procedures during system setup are crucial to prevent air entrapment.

- Poor or Worn Connections: Worn rod seals, loose hoses, suction lines, and connections provide entry points for air. Regular inspection and maintenance are essential to address wear and ensure connection integrity, reducing the risk of combustion.

How to Avoid Dieseling in Hydraulic Cylinders

- Maintain Proper Fluid Levels: Check hydraulic fluid levels regularly to ensure they are at the recommended levels. Low fluid levels can lead to air entering the system and increase the risk of dieseling.

- Use Quality Hydraulic Fluid: Choose the right hydraulic fluid with appropriate properties for your system. Quality fluid reduces the chances of combustion and keeps the system running smoothly.

- Install Pressure Relief Valves: Pressure relief valves help prevent excessive pressure buildup. Avoiding high pressures minimizes the risk of air compression and dieseling.

- Regularly Inspect Seals and Connections: Check rod seals, hoses, and connections for wear and tear. Worn components can allow air into the system, contributing to dieseling.

- Properly Vent the System: Ensure the hydraulic system is well-ventilated to prevent air accumulation. Proper ventilation reduces the likelihood of air bubbles forming in the hydraulic fluid.

- Train Operators: Educate operators to recognize signs of abnormal system behavior. Prompt reporting of issues allows for timely intervention and reduces the risk of dieseling.

- Implement Routine Maintenance: Establish a regular maintenance schedule for the hydraulic system. Regular maintenance helps identify and address potential problems before they escalate.

- Check for Air Leaks: Inspect the system for any air leaks, especially around connections. Sealing air entry points minimizes the risk of air mixing with hydraulic oil.

- Properly Adjust Valves: Ensure that valves are correctly adjusted to prevent pressure spikes. Incorrectly adjusted valves can contribute to air compression and dieseling.

- Monitor Fluid Temperature: Keep an eye on hydraulic fluid temperature. High temperatures can increase the risk of dieseling, so use coolers if needed.

If you have any additional questions or need help choosing hydraulic equipment for replacement, do not hesitate to contact Magister Hydraulics customer support.

Great article, very informative