About Direction Control Valve and Classification

The hydraulic directional control valves can start, stop, and control the direction of the flow. They are classified according to principal characteristics like:

➢ Type of internal spool

➢ Methods of actuation

➢ Number of flow paths

➢ Size

➢ Connections

A basic directional control valve generally consists of a body, spool, spring, and lever. The position of operation includes:

➢ Raise the load

➢ Lower the load

➢ Hold the load

Manually Operated

As the name suggests, these valves operate with simple levers where the operator employs force to treat the valve. The Spring force can be utilized to recover the position of the valve. Manual valves generally use a lever, external pneumatic, or hydraulic signal to return the spool.

Mechanically Operated

These valves implement forces by using cams, wheels, rollers, and likewise. These valves are constrained to wear.

Hydraulically Operated

A hydraulically operated (Digital Control Valve) operates at a lot higher pressure than its pneumatically-driven matching. They need to as a result be even more durable in nature so are accurately machined by higher quality as well as endurance products.

Solenoid Operated

They are extensively used in the hydraulics sector. These shutoffs utilize electromechanical solenoids for the gliding of the spool. Because the basic application of electric power gives control, these shutoffs are utilized extensively. Nevertheless, electric solenoids can not produce huge forces unless supplied with big quantities of electrical power. When invigorated over time, warmth generation poses a risk to the expanded usage of these valves. Numerous have a minimal duty cycle. This makes their straight-acting usage generally limited to low-actuating pressures. Commonly a reduced power solenoid shutoff is used to operate a tiny hydraulic valve (called the pilot) that starts a flow of fluid that drives a bigger hydraulic shutoff that requires more force.

A bi-stable pneumatic valve is generally a pilot valve that is a 3 ported 2 setting detented shutoff. The valve retains its placement throughout the loss of power, hence the bi-stable name. Bi-stability can be achieved with a mechanical detent as well as 2 opposing solenoids or a “Magna-latch” magnetic latch with a polarity delicate coil. Favorable opens up and adverse closes or the other way around. The coil is kept in the setting magnetically when activated.

Type of Spool

Spool consists of two types:

- Sliding

- Rotary

The sliding spool is cylindrical in cross-section, including the lands and grooves as cylindrical. While on the other hand, rotary valves have sphere-like lands and grooves that are present in the form of holes, drilled through them.

Directional Control Valve

The most basic directional control valve is the 2 way valve. A 2 way valve quits flow or allows flow. A single-acting cylindrical tube needs supply to and exhaust from its port to operate. This calls for a 3 way shutoff. A 3 way valve permits fluid circulation to an actuator in one placement as well as tires the fluid from it in the other placement. Some 3 way valves have a third position that blocks flow in all ports.

A 4 way shutoff exhausts and also pressurizes 2 ports interdependently. A 3 position, the 4 way valve stops an actuator or allows it to drift. A 5 way shutoff performs the same feature as a 4 way valve. All spool valves are 5 ported, yet hydraulic valves have internally linked exhaust ports most likely to a common outlet. Since oil has to go back to the tank, it is convenient to attach the twin storage tank ports to a solitary return port. For air shutoffs, the ambiance is the storage tank, so exhaust piping is usually inconsequential. Using 2 exhaust ports makes the shutoff smaller and cheaper. As will be explained later, double exhausts made use of for speed-control mufflers or dual-pressure inlets make this setup functional. The simplest directional control valve is the 2 way shutoff. A 2 way valve stops flow or enables flow. Some 3 way shutoffs have a third position that blocks flow at all ports. A 5-way shutoff does the very same function as a 4 way valve.

2 way hydraulic directional control valves

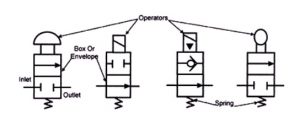

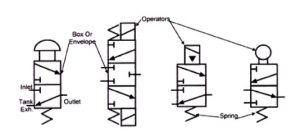

A 2 way directional valve has two ports generally called inlet and also outlet. When the inlet is blocked in the at-rest condition, as shown below, it is referred to as “generally closed”. The at-rest box or the regular condition is the one with the flow lines most likely to and also from it. The boxes or units stand for the shutoff settings. The active box reveals obstructed ports, or a shut condition, while the top box reveals a circulation course.

When the valve is operated, it is the same as sliding the top box down to fill in the reduced box. In the shifted condition flow goes from inlet to outlet. Releasing the switch allows the shutoff springtime to go back to the regular stop circulation problem. A 2 way valve makes a blow-off gadget or runs a liquid motor in one direction. By itself, a 2 way shutoff can not cycle also a single-acting cylinder.

The figure shows a “generally open” (NO) 2 way directional valve. Stimulating the solenoid on this valve quits fluid flow.

A 2 way hydraulic directional control valve has two ports normally called inlets and also an electrical outlet. When a driver changes the valve, it is the same as gliding the upper box down to take the area of the reduced box. Launching the hand button permits the shutoff spring to return to the regular stop flow problem.

3 way hydraulic directional control valves

A 3 way hydraulic directional control valves has 3 functioning ports. These ports are inlet, outlet, and tank (exhaust). This kind of valve does not just supply liquid to a cylinder, yet permits fluid to return from it.

Solenoid pilot operated 3 way valve.

The diagram shows all ports blocked, 3 way, 3 position control valve. This type of valve can be connected to a single-acting, weight or spring-return hydraulic cylinder which can extend, retract or stop at any given time!