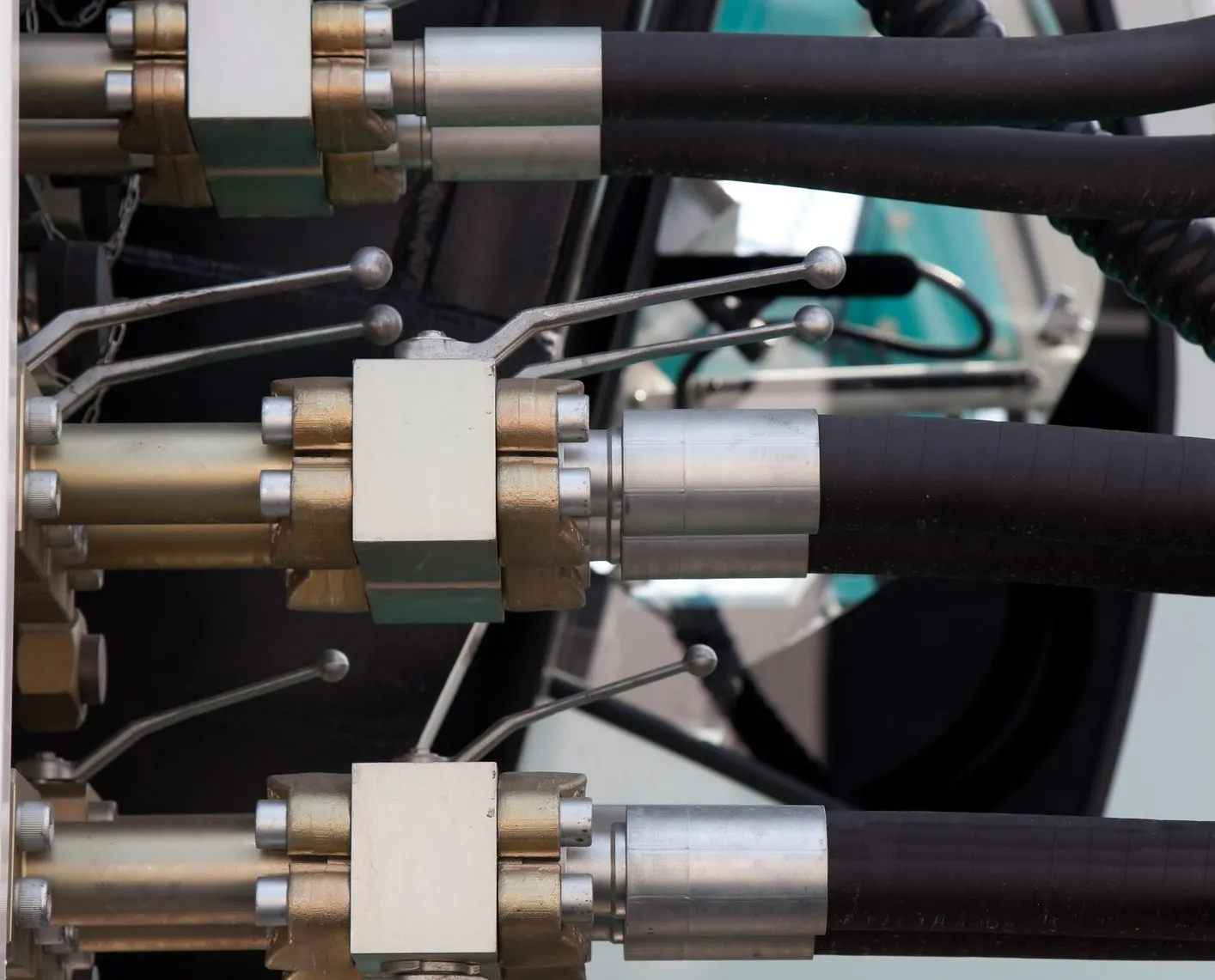

Hydraulic hoses and various couplings are the crucial components of most construction machines and agricultural parts and equipment. You know that couplings and hoses are integral to all hydraulic systems. Wondering why? They transfer fluids from the pump to various machine components, like valves, actuators, etc. And these components change the fluid flow and force. This creates the mechanical force that performs work.

However, like other parts, hydraulic hoses can stop functioning. This malfunction can derail production schedules instantly, costing you considerable time as well as money.

Hose assemblies that suddenly fail or break down are likely to cause injuries, costly cleanup, and property damage? Higher material cost and labor cost are some other issues you may have to deal with.

Depending on your hose, after four to five years of use, the rubber starts to deteriorate. As a result, you may notice visual cracking. Note that if you have a lower-quality hose, it may be sooner than that.

Because of these consequences, many fluid power experts advice replacing hose assemblies before they malfunction.

Hydraulic Hose –Basic Information

Hydraulic hoses move fluid via an effective hydraulic system. Typically, it’s done at higher pressures and speeds. These hoses help operate and function your hydraulic system, whether the system is a modern electric unit on airport runways or excavation equipment at your construction site.

Since they operate at higher pressure, many hydraulic hoses come reinforced and constructed with multiple layers and remain flexible.

A Word on Failure

Several causes and reasons are behind hose failure. And about 80 percent of hydraulic hose malfunctions and failures are because of external damage. Usually, you don’t have to replace your hose unless you find evidence of abrasions and leakage. And a quick visual inspection will help identify one or more reasons for machine hose failures.

There isn’t any reliable or accurate way to confirm just how long your hose assembly may last once you notice these symptoms. So, we recommend that you inspect your hoses, cylinders, and hydraulic valves, frequently. And maintain a comprehensive log of any trouble spots you may find.

Signs and Symptoms Indicating a Need for Replacement of a Hydraulic Hose

The most frequent cause of abrasion is when hose assemblies rub each other or nearby surface? Note that the simplest way to avert hose failure is inspecting them. You should look for many different issues during the inspection.

A couple of signs may indicate that your hose may no longer work. For instance, you may have to replace the hose in these cases:

⦁ Distortion in or crushed hose assemblies

⦁ Worn out marks on a hose that may impair its structural integrity

⦁ Considerable surface damage (in addition to small nicks, marks, and scuffs)

⦁ Exposure of wire within your hose

⦁ Fluid leakage

⦁ Kinks (indicates incorrect routing)

⦁ Twisted hoses (indicates poor routing)

⦁ Corroded fittings

Flexing your hose aggressively and twisting it can lower hose life.

Look out for these signs that the hose on your commercial equipment or agriculture machinery needs replacement. You will be happy to know that habitual inspections can show these problems and issues.

Steps to Replace a Hydraulic Hose Assembly

While you can get professional help and have somebody replace your hose, usually the job is more dirty than complex or difficult. This means you can probably do it. So, if you have no problem rolling up those sleeves and perform the job yourself, you can save some time and valuable money.

Whenever your hose assembly exhibits the signs or conditions above, it is better to change it. You can use these steps to change your worn or failing hose.

⦁ Safety first! Use gloves and other safety tool, such as a pair of goggles and keep yourself safe from dangerous fluid. Hydraulic liquids and fluids could be toxic. It will likely hurt any part of your body that it contacts. So, it is better to secure yourself with safety equipment.

⦁ You should determine the issue with the part. If it is leaking, you must know which hose is effected. Also, know its location before starting. Use cardboard, or some papers, to follow the oil leak. You must perform checking on the broken hose before completely removing it.

⦁ Staying safe is important; so, releasing all pressure timely from the system is essential. Refrain from operating any hydraulic equipment if there’s pressure inside the system as these liquids may spray out and end up hurting you, and you don’t want that.

⦁ Now determine which system parts must be changed in order to get rid of the problematic hose. Considering the situation carefully is crucial to making sure that repairing the part fixes the problem.

⦁ Prep the system and notice any parts connected to your hose assembly. This will ensure that they do not delay the replacement. For example, you should lower components so they don’t fall and you get a clear view.

⦁ Also, get the best tools. For example, use a saw designed exclusively for hoses when changing parts.

⦁ Undo the fittings connecting the hose assembly to your machine. The important part is to release the part that attaches the hose to your main equipment. It’s often the valve spool, the cylinder, or even coupling. Looking to replace multiple hoses? If so, color coding or marking the ends of each is a good idea to maintain proper connections.

⦁ When these fittings are loose, carefully remove your assembly. Now, pour some residual fluid into your waste bin or container.

⦁ Before installing the new part, seal everything with a lint-free rag.

⦁ Use original parts from the OEM to get the best results. This helps ensure that your hoses fit and last a long time. Get the proper hose by simply matching your new part with the former. The thickness and width should be same. Using low-quality parts can significantly damage your machine.

⦁ Clean your new hose and this existing assembly and get rid of debris. All dirt or oil on exterior parts must be cleaned. If your hose is likely to rub against your machine, buy a good abrasion sleeve and minimize the risk of severe damage.

⦁ Installing your new assembly is simple. Use safe and right techniques to reassemble the remaining system. Using the double wrenching method can prevent hose assembly twist. Inserting the first side of your hose is usually simple, as one side is free. Insert one of the ends of your hose into the fitting and then rotate it clockwise.

⦁ Now you can check your new installation. All of the pieces or parts you removed should be back in the right place before you start testing your hydraulic system. Test your new hose assembly.

⦁ Test this hydraulic system after you have replaced the assembly and reassembled your system. There should not be any leaks and performance issues in this new system.

Final Thoughts

All excavation equipment, tractor loaders, and bulldozing machines have one common flaw. These machines are as dependable and efficient as the hoses via which various hydraulic fluids travel. And a sudden rupturing of the hose not just halts your work but it will also lead to a spill that may endanger your environment. Also, if your hose does not break, high-pressure liquid leaking from it can seriously injure your staff

Similarly, extreme temperatures can break down your hoses. It is evident that most hose assemblies will fail at some point in time. If there are any signs on your equipment described above, you can bring in hose assembly vendors to get the best replacement.

Are you looking for the most reliable hose? You can contact the leader in hydraulic manufacturing: Magister Hydraulics. The main goal of our team is to guide all our customers in finding hydraulic products, like cylinders, valves, and control valves, at a reasonable price.

All hoses and gear pumps at Magister Hydraulics are made with top-quality material that prevents corrosion and enhance the functioning of this vital element in the roughest working conditions. Get the best hydraulic products to minimize your downtime and maximize the safety of your workers.