How to determine proper hydraulic hose fittings?

Nowadays there are numerous types of tools and machinery that require a specific kind of sealing. Thread types also vary according to design characteristics and technical features of the equipment. Hydraulic hose fittings are used for the flexible connection of two fluid ports.

Hydraulic hoses are easily installed and uninstalled if necessary. However, at first sight, thread shapes have certain similarities with each other. It complicates the process of identification of the most hydraulic hose fittings for purchase, repair works, or modification of equipment. Here is a 5-step algorithm for the determination of the needed connection.

The simple 5-step procedure to identify hydraulic hose fittings:

Step 1: Define the fitting type

There are two fitting types: permanent (crimped) and reusable (reusable/returnable). In most cases, the crimped type of hydraulic hose is used because the second one is considered the old-school one. New equipment requires a permanent type of fitting that is installed with the help of the crimping tool.

It is worth noting that the hydraulic hose fitting becomes discarded right after the assembly was damaged or something went wrong. To sum up, much more likely you will define the permanent fitting type. If you face old equipment and are doubtful of its origin, check the following signs of reusable fittings:

- No crimping tools are used for its installation.

- The returnable type of fittings is installed on the hose with the help of screwing.

Step 2: Match port connections

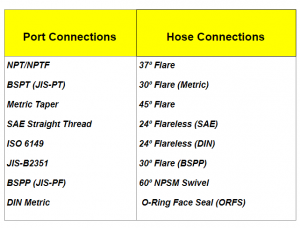

Fitting ends can vary. According to their connection type and the specified end, the proper hose is selected. For example, a 4-bolt flange is one of the connection types. It is suitable for both metric and BSPP (British standard pipe parallel thread) 60⁰ cone tube coupling (hose connection).

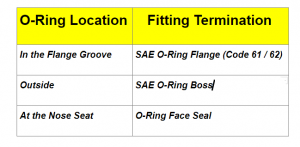

Other possible variants of correct installations are presented in the table below:

Step 3: Identify the sealing type

To find an appropriate fitting, it is necessary to take into consideration prime technical characteristics and their physical dimensions (diameter, size, etc.). Let’s take a look at the main types of hose fittings that have sub-variants.

O-Ring seal designs:

The main purpose of the O-ring sealing technique is to provide the seal itself. Speaking about sub-sorts of O-ring couplings, it is worth mentioning the following three types:

O-ring boss

O-ring boss

Flat face O-ring seal (Female)

Flat face O-ring seal (Female)

O-ring flange

O-ring flange

Mated Angle:

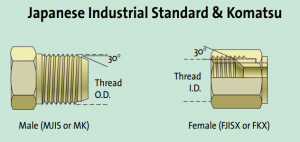

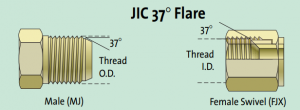

The sealing technique is based on two types of threads: straight and parallel. There are male and female units that form the thread itself. Here are the graphics that describes all the possible variants of the mated-angle type of threads.

Seat Angle Coupling Termination

30°

37°

45°

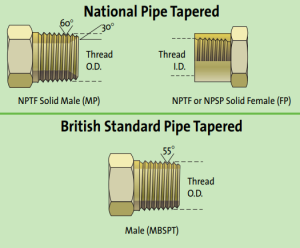

Tapered Threads

This technique is notable with inside-thread female items and outside-thread male ones. The graphical description of the NPT (National Pipe Tapered) and BSPT (British Standard Pipe Tapered) models are presented below:

Step 4: Detect the fitting design with the help of visual analysis

There are various combinations of actual dimensions, O-ring position, seat angle degrees, etc. All aspects should be taken into account. Note that one of the prime features is seat angle determination. This procedure can be done with the help of a seat gauge. The most common fitting terminations were performed in the tables below. Showings are brought up to the sealing type and other characteristics.

O-Ring Face Seal

We take a look at three fitting terminations with flat-faced seats. Seat angle measuring is not required as well. The most necessary factor is the O-ring location:

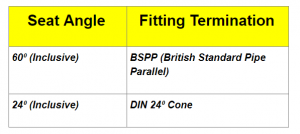

Mated Angle Seat with O-ring

In this case, the nose seat is inverted. Both fitting designs are notable with the inside location of the O-ring. The seat angle should be measured.

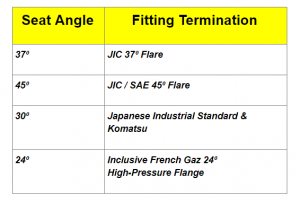

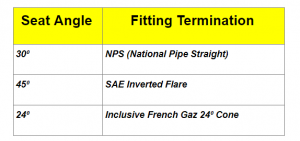

Mechanical Joint / Mated Angle

These sealing techniques do not require O-ring availability. We divided all fitting terminations according to the type of nose seats. Two tables are presented below.

For the standard nose seat

Define the seat angle degree first.

For the inverted nose seat

Define the seat angle degree first.

Thread Interface

There are two types of fitting terminations to take into account: NPT (National Pipe Tapered) and BSPT (British Standard Pipe Tapered). The visual estimation takes place. Additionally, to tables and short descriptions of available fitting designs, there is a table with visual examples for more information.

Graphical Presentation

Step 5: Identify the Tread Size

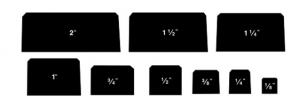

You need a thread gauge to initiate the measuring. Note that thread is determined in inches. In the following pictures, both cone and hex showings are presented. Use these diagrams for an easy determination process.

Male Pipe Thread Sizes

Flat Nose (Cone) Sizes

Nut and Nipple Hex Sizes